There’s a push for electrification in the worldwide automotive industry today, but it’s certainly not the first initiative to reduce the carbon footprint from vehicles. Emissions standards as well as fuel economy targets have been around for decades, aimed at reducing the greenhouse gases produced from burning the fuel required.

Batteries are also part of the equation, not just in terms of reducing tailpipe emissions, but also in mitigating waste and contamination from batteries themselves. The rise of eco-friendly initiatives bridges from vehicle manufacturing to maintenance and usage. Learn more about how battery diagnostics integrate into green practices, and how Midtronics is a leader.

The Environmental Impact of Batteries in the Automotive Industry

As the automotive world moves toward greener solutions, batteries have become a focal point in both the environmental challenges and opportunities. Whether in traditional combustion engine vehicles, hybrids, or EVs, batteries play a crucial role. However, they also come with a significant environmental footprint, from production all the way through disposal.

One major issue is the environmental toll of producing these batteries. Many of the materials required for EVs and hybrids like lithium, cobalt, and nickel need to be mined, which can cause serious damage to ecosystems. This includes everything from habitat destruction and soil erosion to water pollution. On top of that, the manufacturing process itself is energy-intensive, often resulting in higher greenhouse gas emissions. So, while batteries are a critical part of the solution for greener transportation, their production creates its own environmental hurdles.

Then there’s the challenge of what happens when batteries reach the end of their useful life. If not properly disposed of or recycled, batteries can leak harmful chemicals into the environment. For example, lead-acid batteries contain hazardous materials like sulfuric acid and lead, which can contaminate soil and water. Lithium-ion batteries, which are common in electric vehicles, have their own risks, including the potential to catch fire if damaged or improperly handled. All of this makes responsible disposal and recycling more important than ever.

How Battery Diagnostics Factor In

To address these challenges, the automotive industry is increasingly focused on better managing the entire lifecycle of batteries, from production to disposal. Recycling, repurposing, and reconditioning used batteries are all gaining traction as ways to reduce waste and minimize environmental harm. This is where advanced battery diagnostics come into play.

Extending Lead-Acid Battery Lifespan

For lead-acid batteries that are still so commonplace, recycling is surprisingly efficient. Typically, 99% of the materials contained, including lead and the materials composing the case, are recycled for new battery production or other industries. The major impact comes from disposal. Batteries that end up entering landfills can leach into soil and water, causing long-term pollution. And the solution is primarily to extend their lifespan as much as possible.

Routine testing is an exceptionally effective method, identifying issues that could be causing the battery to be strained. If batteries can be properly recharged and strenuous conditions avoided, they can last longer than the 3-year lifespan that’s so commonly stated.

One factor that has dramatically changed replacement frequencies and reduced waste has been the increasing prevalence of EFB and AGM batteries. Known to last years longer than a standard lead-acid battery, they reduce replacement intervals by as much as a factor of two.

Reducing Fuel Consumption

For the majority of vehicle models produced today, auto start-stop is a feature intended to trim fuel consumption by as much as 10%. It centers around the battery, though, and if it doesn’t have a sufficient state of charge when the vehicle comes to a stop, auto start-stop doesn’t engage, and the engine continues to run and burn fuel.

A healthy battery is central to maintaining the best fuel economy in these models. Over the course of a year, the average light truck burns 636 gallons of fuel, for example. An increase of 63 gallons comes at a substantial cost, whether you’re paying $3 per gallon or more than $6 per gallon. This is a real-world example of what happens when the auto start-stop feature won’t engage because the battery isn’t healthy enough to allow it.

Battery diagnostics really do contribute to green technology working properly, and again, routine testing and battery replacements help out. Fortunately, EFB and AGM batteries are required for these tech-heavy models, but the need for testing is nonetheless important.

EV Battery Health

What’s currently the pinnacle of operating economy is electrification, as we know. A full charge costs just a fraction of what a full tank of fuel costs on a comparable model, but that requires the battery to stay healthy for as long as possible. Replacing a battery pack is an exceptionally cost-prohibitive repair, and it wipes away any cost benefit that’s present within the first 10 years, and often an even longer term.

When EV batteries are replaced before their estimated lifespan, that increases the demand for procuring the raw materials to manufacture new ones, and the effects have already been mentioned about that. It can be argued that battery packs can be repurposed for second-life projects like solar farms or emergency battery backups, but the effect is still present.

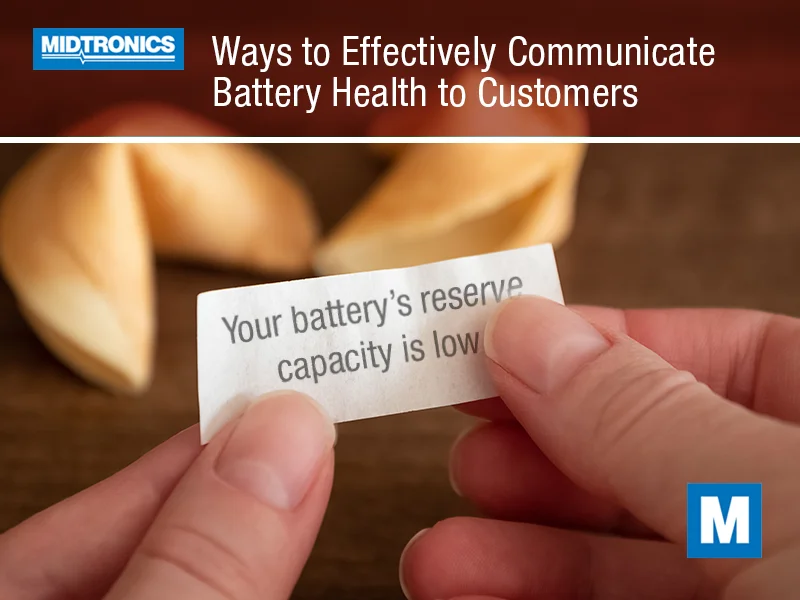

Scheduling EV battery diagnostics as a routine checkup for vehicle owners can be perceived by owners as unnecessary, but they’re ideal for identifying anomalies that can shorten the battery pack’s lifespan – issues that could be corrected with a cell or module replacement and subsequent battery module balancing. These processes not only save a monumental expense for the customer down the road, but reduce environmental impacts, downtime, tainted customer experiences, and high-cost warranty claims.

Don’t Mistake the Importance of Battery Checks

It doesn’t matter what type of vehicle customers drive – ICE, EV, or hybrid – battery health is important for operating as green as possible. Automotive repair facilities play a large part in not just performing the diagnostics to ensure batteries are healthy, but educating customers on how best to keep their cars operating as efficiently as they’re designed to be.

With routine maintenance, keep battery testing a prominent item. Midtronics is the leader in manufacturing equipment that supports service centers, dealerships, and repair shops, and our tools make testing quick and easy.